Industry 4.0 Sector: Responsiveness That Leads to Improvement

Industry 4.0 represents a new era in manufacturing, marked by a fusion of advanced technologies that blur the lines between physical and digital systems. This transformation emphasizes smart automation, data exchange, and real-time monitoring, allowing businesses to be more responsive and adaptive than ever before. But how exactly does this increased responsiveness lead to improvement?

At its core, Industry 4.0 leverages technologies like the Internet of Things (IoT), artificial intelligence (AI), and big data analytics to create interconnected systems that continuously collect and analyze data. This real-time data flow enables companies to monitor production processes closely and make immediate adjustments, ensuring optimal performance. For example, sensors embedded in machinery can detect potential issues before they become critical, allowing for preemptive maintenance that reduces downtime and enhances productivity.

Furthermore, the integration of AI allows for predictive analytics, where systems anticipate and respond to changes in market demand, material supply, or production capabilities. This agility helps companies not only avoid disruptions but also capitalize on emerging opportunities. Imagine a factory that can instantly adjust its output to meet a sudden surge in demand or switch to alternative suppliers when faced with shortages. This kind of responsiveness is a game-changer, leading to better resource utilization and customer satisfaction.

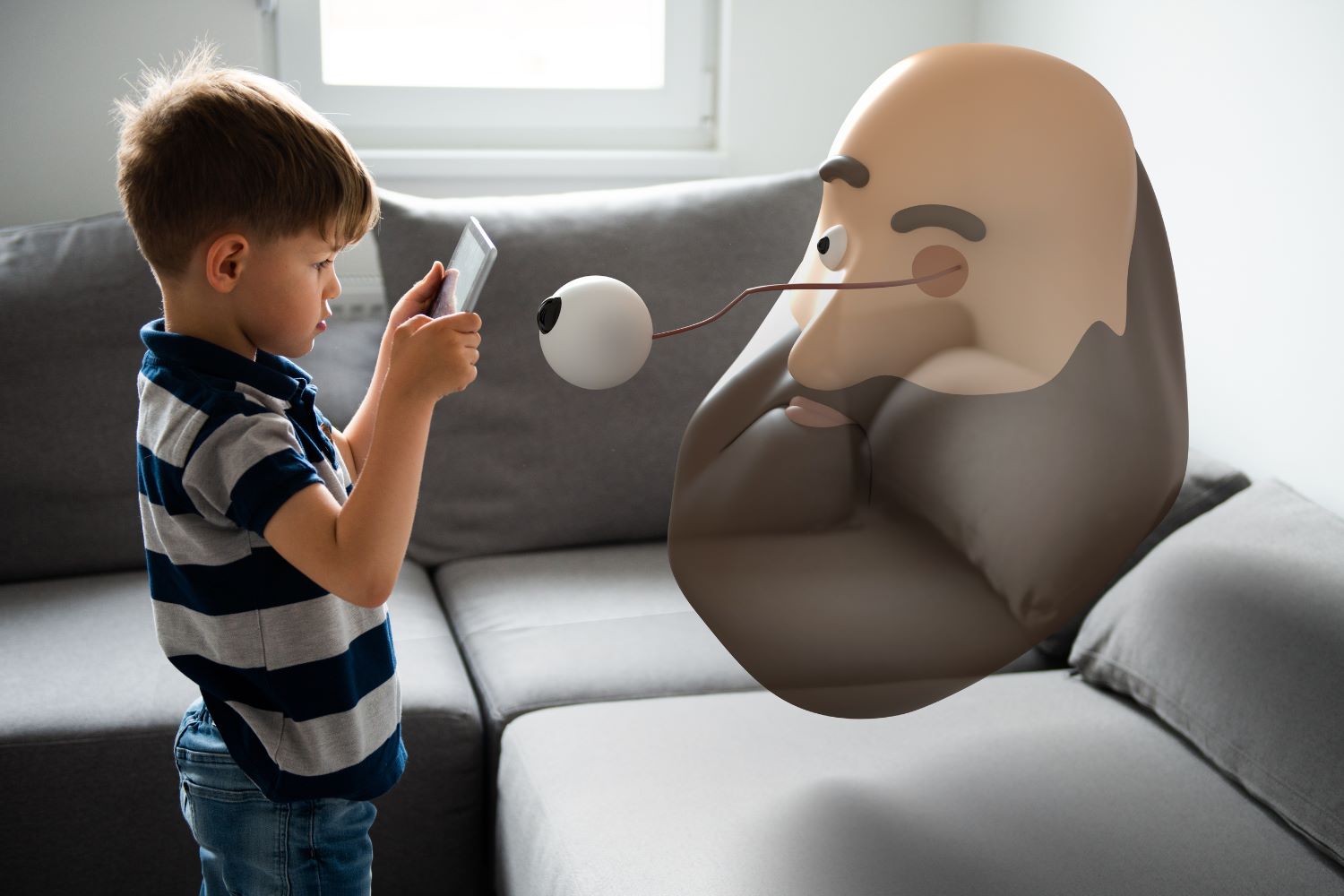

Another key aspect is the role of human-machine collaboration. Workers are now equipped with smart tools and interfaces that provide real-time insights and automation support, allowing them to make more informed decisions quickly. This synergy between human intelligence and machine efficiency enhances the overall productivity and quality of the manufacturing process.

In conclusion, the responsiveness facilitated by Industry 4.0 technologies fosters a dynamic and efficient manufacturing environment. By enabling real-time adjustments and predictive capabilities, these innovations lead to continuous improvement, ultimately driving competitiveness and growth in the modern industrial landscape. As businesses continue to embrace these advancements, the potential for further enhancements and innovations in manufacturing seems boundless.